ZEISS CT and X-ray Systems Make the Invisible Visible

ZEISS Industrial CT and X-Ray technology is now easier and more cost effective than ever before. X-raying parts serves up a plethora of potential new applications – from inspecting internal defects and the dimensional measuring of internal structures to structural material analysis. The once hidden is now visible – thanks to X-ray solutions from ZEISS. X-ray solutions from ZEISS perform advanced, non-destructive quality control. Make the invisible visible – and be absolutely sure about the quality of your parts.

Whether precise measurement, fast inspection or analysis down to the nanometer scale, ZEISS CT and X-Ray has the right solution for whatever your manufacturing application – with high-precision CTs, automated 2D and 3D X-ray systems, and high-resolution 3D X-ray microscopes. Automotive, aerospace, medical technology, electronics, consumer goods … no matter your industry, the possibilities are endless, and so is the savings.

METROTOM Computed Tomography

ZEISS METROTOM 1 Computed Tomography System

Inspect the invisible in one scan. The ZEISS Metrotom 1 is the newest level of simplicity. The easy-to-use CT technology of the ZEISS Metrotom 1 means anyone can efficiently perform complex measurement and inspection tasks with just one scan. Measure and inspect hidden defects and internal structures that cannot be detected with tactile or optical measuring systems.

ZEISS METROTOM 6 scout Computed Tomograph

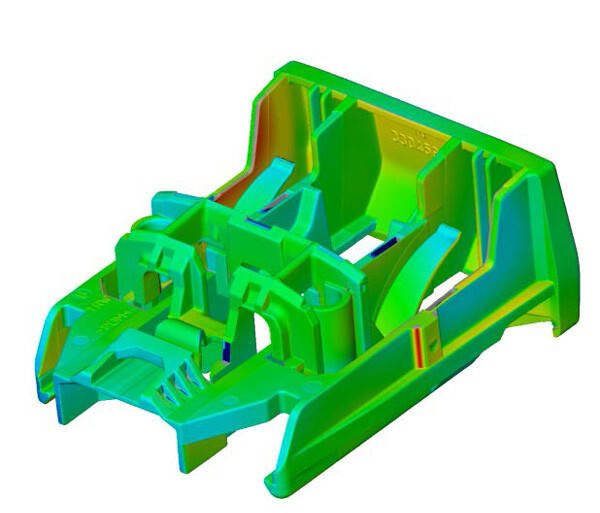

The ZEISS METROTOM 6 scout is the powerhouse of resolution for CT inspection and metrology. High-resolution images can be captured for precise measuring tasks or detailed inspections of internal structures. Be it shrinkage holes, pores, cracks, sink marks or warpage – all defects or deviations from the CAD model can be detected non-destructively with the ZEISS METROTOM 6 scout (GOM CT).

You need to measure your parts accurately or find the smallest defects on the inside? With ZEISS METROTOM 6 scout this is no problem at all. The system’s high accuracy and resolution generates accurate and detailed measurement and inspection results. Additionally, you can carry out further analyses such as dimensional analyses, as well as wall thickness analyses or target/actual comparisons.

ZEISS METROTOM 800 and 800HR Computed Tomograph

The ZEISS METROTOM is an industrial computed tomography system for measuring and inspecting complete components made of plastic or light metal. With traditional measuring technology, hidden structures can only be inspected after the time- and cost-consuming process of destroying the component layer-by-layer.

ZEISS METROTOM 1500 Computed Tomography System

When accurate CT technology meets industrial performance. The third generation of the computed tomograph (CT) ZEISS METROTOM 1500 provides the best evidence that advanced and reliable X-ray technology is no longer a vision of the future. You can future-proof your non-destructive quality control – today.

In the third generation, a new 3k detector generates 3D volume data sets with higher resolution, i.e. more voxels permitting the detection of smaller defects. And, in order to get the most out of your space in your measuring lab, the measuring volume was extended while reducing the footprint. Measure and inspect parts up to 870 mm in height on 6.7 m² – the best system/part volume ratio available on the market.

VoluMax CT Systems

VoluMax Inline Computer Tomograph Systems

With VoluMax you can inspect 100% of your components for manufacturing defects – automated and inline. You receive information about component porosity or the correct configuration of assemblies within seconds. Your benefit is simple fast thoughput and you deliver only fully tested components to your end customers.

ZEISS VoluMax 400/800 Computed Tomograpy Systems

VoluMax M400: Fast inline metrology of small plastic parts

VoluMax M800: Inline metrology of mid-sized plastic parts

VoluMax F800: Fast inline inspection of mid-sized parts

ZEISS VoluMax F1500 Computed Tomograpy Systems

VoluMax F1500: Fast inline inspection of large parts

VoluMax F1500 Thunder: Fastest inline inspection of mid-sized parts

ZEISS VoluMax 9 flash CT

Very fast inline inspection of very large parts. Cycle times can be quite a challenge when inspecting large casting. ZEISS VoluMax 9 flash is the optimal solution for automated 100% inspection of large parts at high speed. The specially developed large detector allows you to scan parts such as engine blocks up to 30% faster – 24/7 and without any required cooling in between the scans. High throughput and cycle times of less than 60 seconds are easier than ever before.

ZEISS VoluMax 9 titan CT

Fastest inline inspection of mid-sized parts. Delivering 450 kV performance while maintaining a remarkably small footprint, the ZEISS VoluMax 9 titan is the most compact and robust system of its kind on the market. Not only can its spacious interior accommodate parts measuring up to 590 x 700 mm and weighing as much as 60 kg, its 3k detector and 1,500 W power range offer outstanding penetration strength – all of which is vital for handling the large and dense components that characterize the battery module segment.

BOSELLO Industrial X-Ray Imaging

High Resolution 3D X-Ray Microscopy and Computed Tomography

BOSELLO High Technology, a ZEISS company, produces radioscopic industrial units to control product quality through X-Ray. BOSELLO boasts applications in many sectors including automotive, aerospace, foundry, and piping.

MSI Viking expert engineers can help guide you to the perfect machine for your specific needs.

ZEISS BOSELLO HEX X-Ray System

ZEISS BOSELLO HEX 50.70 MAN X-Ray

ZEISS BOSELLO HEX 50.70 CNC X-Ray

The BOSELLO HEX enables fast inspections of small to mid-sized castings in a very small place – for everyone. With this system you c an flexibly configure your optimum 2D X-ray solution that fits your needs and your budget. With its robust design ZEISS BOSELLO HEX is perfectly built for the production environment. The cabinet is completely self-contained and allows easy transportation and installation.

ZEISS BOSELLO HEX X-Ray System

ZEISS BOSELLO MAX 70.120 CNC

ZEISS BOSELLO MAX 80.150 CNC

ZEISS BOSELLO MAX 100.150 CNC

The BOSELLO MAX is application versatile. A system that really fits your needs! High flexibility and many configuration options make ZEISS BOSELLO MAX the perfect match for 2D and optionally 3D X-ray inspections of different types and sizes of castings.

Its robust design is perfectly built for the production environment. The light-weight construction is completely self-contained and allows easy transportation and installation. The controller panel is directly attached to the system saving you valuable space, and a lower cost of ownership.

BOSELLO WRE THUNDER X-Ray System

Inspect Wheels at Full Speed with the ZEISS BOSELLO WRE Thunder

Fast 100% inspection of light alloy wheels

Inspection of a large number of different wheel models

Designed for long and continuous use in a harsh industrial environment

Optimized automatic wheel position identification for fully automated inspection

ZEISS BOSELLO OMNIA

ZEISS BOSELLO OMNIA 120.70

ZEISS BOSELLO OMNIA 160.100

Turning inspection into productivity.

Inspection of different parts with different sizes

Time savings due to parallel inspection and loading possibility

Adaptable set-up for a completely customized and flexible solution

Can be integrated into production lines

Xradia X-Ray Imaging Solutions

The Xradia Versa family of submicron XRM uses patented X-ray detectors within a microscope turret of objectives for easy zooming down past 700nm spatial resolution with minimum achievable voxels of 70nm. The Xradia Ultra family of nanoscale X-ray microscopes is the only commercially available X-ray microscope that utilizes synchrotron quality X-ray optics and provides true spatial resolution down to <50nm and minimum achievable voxels of 16nm.

ZEISS Xradia 410 Versa – It’s a 3D Submicron Imaging Workhorse

Xradia 410 Versa bridges the gap between high-performing 3D X-ray microscopy solutions and traditionally lower-cost, less capable projection-based computed tomography (CT) systems. Multiple source options provide flexibility for imaging a wide range of sample sizes and types. ZEISS Xradia 410 Versa X-ray microscope delivers cost-efficient, flexible 3D imaging to enable you to address a wide range of samples and research environments.

ZEISS Xradia 510 Versa

Based on the award-winning design of its predecessor, Xradia 510 Versa is the foundation of the Xradia Versa family for those who need the highest 3D imaging capability without the advanced features and performance of the flagship product. Now with FPX flat panel extension.

ZEISS Xradia 610 & 620 Versa Non-destructive 3D X-Ray Imaging

Unlock new degrees of versatility for your scientific discovery and industrial research with the ZEISS Xradia 600-series Versa 3D X-ray microscopes (XRM): the most advanced models in the ZEISS Xradia Versa family. Building on industry-leading resolution and contrast, ZEISS Xradia 600-series Versa extends the boundaries of non-destructive imaging for maximum flexibility to accelerate your research.

ZEISS Xradia 800 Ultra – Achieve Resolution Down to 50 nm

With the ZEISS Xradia 800 Ultra X-ray microscope, you achieve spatial resolution down to 50 nm, the highest among lab-based X-ray imaging systems. With nondestructive 3D imaging playing a vital role in today’s breakthrough research, you will experience unparalleled performance and flexibility in the lab.

ZEISS Xradia 810 Ultra – High Speed Nanoscale X-Ray Imaging

Xradia 810 Ultra increases the throughput of nanoscale, three-dimensional X-ray imaging by up to a factor of 10. This innovative X-ray microscope (XRM) operates at 5.4 keV, a lower energy that delivers better contrast and image quality for medium to low Z samples and other materials used throughout scientific and industrial applications.

ZEISS Xradia Synchrotron Family

Xradia Synchrotron solutions bring nanoscale X-ray imaging to your synchrotron facility, enabling you to forgo costly and time consuming in-house development. Proprietary X-ray optics and a proven 3D X-ray microscopy platform leverage the ultra-bright, tunable X-ray beams available at modern synchrotron facilities.

ZEISS Xradia Context microCT – Precisely Tailored to Your Applications

Xradia Context microCT is a large field of view (FOV), nondestructive 3D X-ray micro-computed tomography system. ZEISS Xradia Context is your imaging solution for a variety of 3D characterization and inspection needs, spanning from large intact samples to reveal interior details in their full 3D context, as well as small samples at maximum geometric magnification to resolve fine features with high resolution and high contrast.