TECHNICAL CLEANLINESS ANALYSIS IN MANUFACTURING PROCESSES

Identify the Root Cause.

Make the Right Decision Faster

When particles/contaminants interfere with manufacturing processes, how do you PROVE clean is clean enough? How do you identify the root cause of contamination? Simply purchasing an instrument will fall way short of a solution. An all-encompassing approach to the implementation of technical cleanliness and contamination control is necessary.

Technical Cleanliness Analysis (TCA) requirements are fast becoming the norm in manufacturing today. Customers are demanding cleanliness of parts that adhere to industry standards for precision machined parts, castings, electronics, and any place where high tolerances must be maintained.

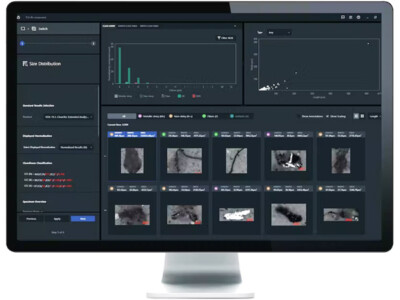

Image Analysis from Light Microscopy to Electron Microscopy The ZEISS portfolio enables combined particle detection and classification in a highly efficient workflow that not only finds particles, but also classifies them according to the origin of the contamination. With ZEISS, you can combine data from light and electron microscopes in a single work process to obtain additional information. In this way, obtain well-founded insights into the cause of contamination.

Access Our TCA Library

MSI-Viking is the ZEISS Authorized National TCA Distributor using Zeiss microscopy solutions. MSI Viking partners with the Gläser Group to provide particle extraction units and consulting services. Our customers come to us in need of an all-encompassing approach that includes a complete portfolio of high-quality equipment, consulting, and continued customer service.

Book a Virtual Demo

Get a Free, No Obligation TCA Demonstration right at the comfort of your own desk.

Cleanliness Compliance is a Growing Concern

ZEN Technical Cleanliness Analysis (TCA) provides industry standards compliance in Automotive, Medical Device, Oil Industry, Aerospace, Precision Machine applications, and many others.

Industry Standards include ISO 4406, ISO 4007, NAS 1638, SAE AS 4059, VDA 19.1, VDA 19.2, ISO 16232, VDI 2083 and more. Reach out to MSI Viking for a complete list and guidance in your industry.

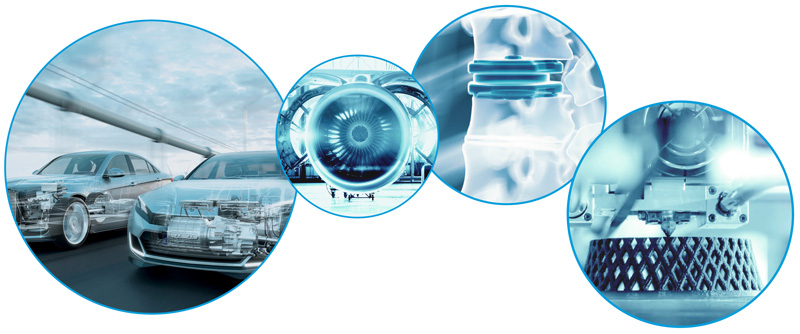

Simple Yet Flexible Software for Analysis Incorporating AI and Customizable Reporting

Make Smarter Decisions Faster with MSI Viking/ZEISS Technical Cleanliness Solutions

Speed Up Your Workflow with One Scan Technology

It’s More than Just Buying a Microscope.

Cleanliness is a System…a Workflow that is integrated into your facility. Speed up your workflow using one scan technology with patent applied for camera acquisition. Detect metallic, non-metallic, and fiber particles in a single scan for a 50% increase in throughput.

Gläser is a very well-established company. With subsidiaries in the USA, China, and Mexico, as well as numerous distributors, the family company based in Horb, Germany is well represented on the international stage. Regular training courses, lab audits, and extraction units guarantee that the same standard of quality is achieved all over the world.