Coherix Inspection Solutions

Coherix designs and delivers high-speed, high-definition, 3D metrology and inspection tools for product development and the management of manufacturing processes for the precision manufacturing and semiconductor industries. Coherix is committed to providing the highest performance 3D vision machines with the lowest cost of ownership over the product’s lifetime. The resulting 3D data enables manufacturers to decrease cost and shorten time to market by preventing unscheduled downtime, eliminating scrap, and increasing throughput.

Coherix Metrology Highlights

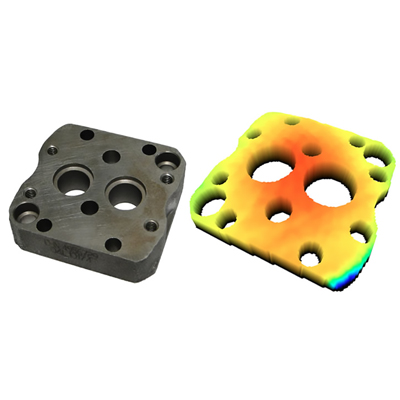

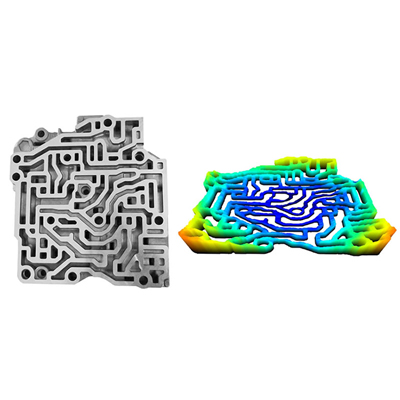

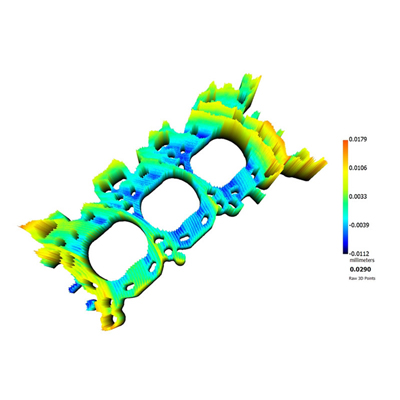

Shapix 3D High Resolution & High Speed Surface Profile, Flatness & Waviness Measurement

The Coherix ShaPix Surface Detective generates high-resolution, 3D images – providing immediate, actionable information for process control in precision machining and manufacturing. All ShaPix solutions are designed to measure the profile, flatness, and waviness of planar surfaces. This technology produces measurements in easy-to-understand, high-definition 3D pictures and reports within minutes. The micron level visualizations produced by ShaPix enable clear understanding and communication throughout the life of a planar surface – from design to production to consumer function.

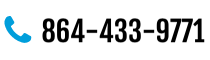

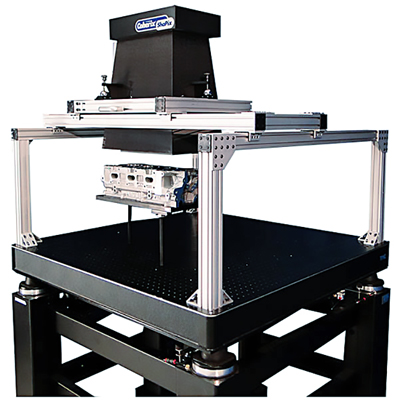

The ShaPix 1500 Series is designed with the flexibility to be configured for specific application needs and is ideal for measuring parts less than 50 pounds. Regardless of the configuration, this metrology solution comes with the full ShaPix areal surface analysis software. With a small footprint, this solution is ideal for incorporation into a variety of spaces.

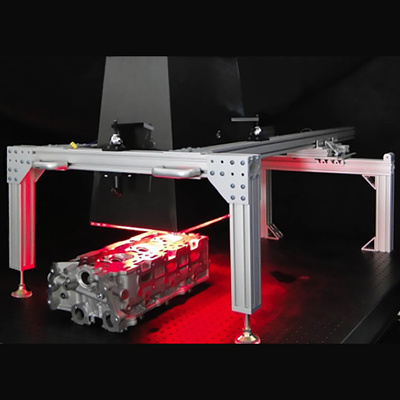

The ShaPix 3000 Series includes models 3700, 3800 and 3120. All built on the ShaPix technology, these machines are configured to measure a large variety of parts. The difference between each system is based on their measurement cavity and their part-entry mechanism. Industrial and plant-floor proven, the ShaPix 3000 Series systems have a large field of view and can measure a V8 deck face in two shots – providing the full surface profile faster than ever. With more than 4 million points of data, 50 nanometer vertical resolution and 150 micron lateral resolution, part shape and form can quickly be seen and understood, providing fast feedback for process control improvement.